Adhesion Strength

Adhesive Bond Strength

Adhesives offer greater bond strength compared to welding and mechanical joints without compromising the strength of the substrate or coating. To select the appropriate adhesive for your application, several factors must be considered. Understanding adhesive bond strength and how to measure it can assist in choosing the right adhesive.

The bond strength of adhesives is measured using three tests: tensile strength test, shear strength test, and peel strength test. These tests are crucial in determining the effectiveness of the adhesive and its ability to bond to the desired substrate.

Scientists examine different bonding mechanisms to assess an adhesive’s capability on various surfaces. Measuring the “adhesive effectiveness” for a joint helps determine the strength of a bonded assembly. A common method for measuring this parameter involves separating the bonded joint using a proportional force. The force required to detach the joint helps engineers gain a better understanding of the adhesive’s performance in different applications.

Bond Strength

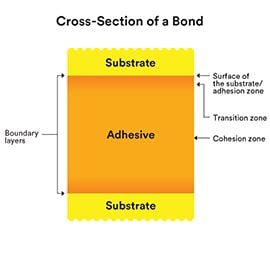

The surface tension strength between the adhesive and the substrate is usually the most critical parameter in designing a bonded assembly. However, bond strength alone does not guarantee a complete connection. Even with the strongest adhesive, if the adhesive does not have good compatibility with the substrate, the bond will fail.

Cohesive Strength (Internal Adhesion)

Cohesive strength refers to the internal strength of an adhesive—essentially its ability to withstand pressure and maintain integrity under stress. The higher the cohesive strength, the stronger the adhesive. Cohesive strength is determined by the chemical composition of the adhesive. The strength of adhesives varies widely, from pressure-sensitive adhesives to structural epoxy and acrylic adhesives. Understanding the types of stresses acting on the joint is crucial. Common stresses include shear, peel, bending, and tension. Knowing the magnitude and frequency of the applied stresses is vital in selecting an adhesive with optimal cohesive strength.

Surface Energy

Surface energy is a physical property of the substrate that determines whether the adhesive will create a fundamental and essential contact with the surface. In a material with high surface energy, the liquid (adhesive) penetrates the surface and wets it; in a material with low surface energy, the liquid resists penetration and beads up.

For suitable bonding, the adhesive must spread across the substrate. Understanding the surface energies in the assembly and how the adhesive spreads on the substrate is critical when selecting the right adhesive. Surface cleanliness should also be considered, as some adhesives require a high degree of substrate cleanliness.