Six practical questions to choose the glue you want

The following questions will help you narrow down the choice of glue for yourself.

What materials should be glued together?

Structural adhesives work by adhering to the top surface of parts, so it’s important to know the exact materials and conditions on those surfaces. For metals, will the adhesive be applied to the raw metal, or will there be a paint or coating on the surface? For plastics, which base resin is considered? Will there be residual release agents on used surfaces to release the mold?

What is the final time taken?

The selected structural adhesive must have sufficient curing time to allow for mixing and application of the adhesive and assembly of the bonded parts. Smaller assemblies or manufacturing processes with short cycle times may be able to use a structural adhesive with a cure speed of five minutes or less, while larger assemblies that require alignment and maintenance will likely require cure times in excess of 20 minutes.

What is the level of preparation required?

Structural adhesives generally prefer clean, dry, oil-free surfaces for adhesion. This usually means cleaning the surface with a solvent, or cleaning the solvent and then chemically or using a primer.

What types of joints are suitable for structural adhesives?

Joints that allow the adhesive to adhere to tensile or compressive shear forces provide the highest resistance. A connection that is subjected to shell or gap forces, contact forces, and torques will have lower bond strength, but may be sufficient for your application needs. In addition, the optimal adhesion line thickness is usually in the range of 125 to 500 microns. The adhesive performance verification process should always include tests of sample aggregates to ensure that the structural adhesive will provide adequate performance.

How are structural adhesives used and applied?

Structural adhesives are available in various forms, including low-viscosity liquids, no-drop pastes, one- and two-component formulations, short and long working lives, and various sizes and shapes of packaging. Most two-part structural adhesives

Available in bulk containers and practical mixing containers.

What are the general characteristics of different types of structural adhesives?

All structural adhesives have at least 7 megapascal shear resistance to aluminum. But different glues have different properties.

Epoxy adhesives are two-component (combined by combining two components) and single-component (which dries with temperature). These adhesives generally have the highest strength and performance. They also provide the best resistance to heat, solvents and weather conditions. These adhesives stick to metals, wood and concrete. Epoxy adhesives are flexible, they stick to some plastics and rubbers. Epoxy adhesives require clean, scratch-free surfaces to achieve maximum bond strength.

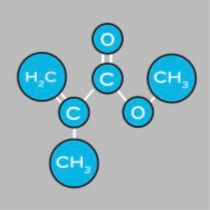

Acrylic adhesives are two-component and provide excellent adhesive strength and durability (slightly less than epoxy adhesives). The main feature of this glue is ease of use and easier production process. Also, they have a very high drying speed, higher tolerance for greasy or unprepared surfaces, and the ability to stick all plastics. New formulations of acrylic adhesives are stable at room temperature and have a longer life for use; Also, they have less smell than common acrylic adhesives. It should be noted that acrylic glue is different from acrylic cement paste.

Urethane adhesives are two components that have a relatively high drying time, which is why they have excellent impact resistance and good adhesion to most plastics. They also adhere well to wood, concrete, and rubber, but are generally less resistant to solvents and high temperatures. Undried glue is sensitive to moisture and does not complete the resistance.

Cyanoacrylate adhesives (instant adhesives) are single-component liquids with low viscosity that dry very quickly with ambient air and humidity. They stick well to plastics, metals and rubber. Using primers, they can bond to low surface energy plastics and elastomers. Compared to structural adhesives, these adhesives have less flexibility, shell resistance, and impact resistance. It is generally used for gluing objects and small parts.

Anarabic adhesives are single-component adhesives that dry in contact with metal and in airless conditions. The property of chemical resistance creates good vibration and shock in connections. Due to the liquid nature of these adhesives, the gaps between the surfaces or threads are well filled and therefore provide complete protection against leakage and rust.

PUR adhesives (polyurethane-reactive adhesives) are single-component adhesives made from urea polymers with isocyanate-based chemicals; These adhesives dry like the hot-melt process, but with the humidity of the environment, they become close to structural adhesives. In 24-48 hours, they can achieve a maximum shear strength of 7 MPa. These adhesives are flexible and resistant to high temperature and most solvents. It is mostly used in cases where at least one subsurface contains or transmits moisture (such as automotive industry, packaging industry, wood industry, printing industry, shoe industry and construction industry).