Cyanoacrylate adhesives

Cyanoacrylate is a general name for a group of fast and very strong adhesives that have many uses in household, medical and industrial applications. Cyanoacrylate adhesives have a short shelf life, so they can be used up to one month after opening and up to one year after production. They are also slightly toxic. These glues are sometimes known by the general name of instant glue or drop glue and the type with activator spray is known as one two three glue. In English, the brand name Superglue is common for this type of glue.

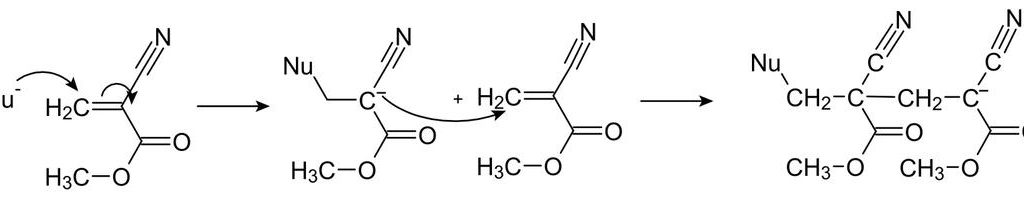

Cyanoacrylates are liquid monomers that polymerize by being placed between two surfaces and forming a thin film. A very small amount of moisture on the surface can cause the glue to dry very quickly (in less than 2 seconds).

In other words, the cyanoacrylate glue will only combine with the surface if there is a little moisture for bonding, and if this glue is placed in a moisture-free environment, it cannot establish any connection.

There are different types of cyanoacrylates that differ in terms of chemical base and concentration level.

- Ethyl ester base: Due to the size of the molecules and the anchor points created that are far from each other, high elasticity and strong connections are created, which are suitable for sticking rubbers and plastics.

- Alkoxy-ethyl base: These adhesives have good flexibility due to their special base characteristics and similar molecular structure. Another characteristic of these products is their low odor, which can be easily used, especially in production lines. These adhesives are less sensitive to moisture after drying and are usually used in places where the white color should not be seen after the adhesive dries for visual reasons.

- Methyl ester base: Due to the small molecular structure and closer anchor points, these types of adhesives are less flexible after drying. Products with this base are suitable for bonding metals.

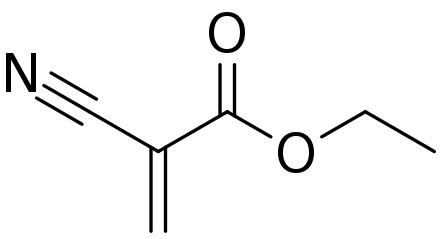

The most common monomer is ethyl 2-cyanoacrylate. Several related esters are known.

In general, the C=C groups rapidly grow in the presence of water in the growth polymerization, forming long and strong chains and bridging the bonding surfaces. Since the presence of moisture causes the adhesive to stick, exposure to normal levels of humidity in the air will cause a thin skin to form within seconds, which will greatly slow the reaction. Hence, cyanoacrylates are applied as thin coatings—rather than thick coatings—to ensure that the reaction proceeds rapidly for bonding.

General features

This substance in liquid form consists of monomers of cyanoacrylate ester molecules.

Methyl 2 cyanoacrylates have a molecular weight of 111.1 g/mol and a flash point of 79 degrees Celsius or 174 degrees Fahrenheit and a density of 1.1 g/mol. Ethyl 2 cyanoacrylates also have a weight of more than 125 grams per mole and a flash point of more than 75 degrees Celsius or 167 degrees Fahrenheit. In order to improve the use of the mentioned adhesive, this material is recently combined with materials such as fumed silica to obtain a sticky or gel-like state. A variety of additives are added to this resin to increase its shear strength and create an impact-resistant compound like rubber.

In general, acrylic groups quickly undergo chain addition processes in the presence of water (especially hydroxy ions) and also produce long and strong chains that connect bonding surfaces to each other. Since the presence of moisture makes the adhesive hard and stiff, exposing a small amount of moisture to the air creates a thin layer of these materials within a few seconds and ultimately slows down the reaction speed, while cyanoacrylates are used as thin coatings to ensure that the connection does not slow down. The lifespan of using this glue is very short, and if it is not opened, it will take about a month from the time of production until this glue becomes unusable. The reaction of this substance with moisture makes the container that has been opened or used become unusable faster than unopened types. In order not to perform such a reaction or to reduce the life of this material, the glue should be placed in packages containing silica gel dryers. Another method is to use hypodermic needles in the entrance part of the glue tubes. Using this method, the glue sticks to the needle and prevents moisture from entering. Before use, the needle can be removed by applying heat to the glue. The reaction of this substance depends on the temperature and if it is placed at a temperature lower than the freezing temperature of water or zero degrees Celsius (or 32 degrees Fahrenheit), this reaction stops. Therefore, it can also be placed in the freezer.

Note: Cyanoacrylate-based glue has a weak bond with smooth surfaces and therefore rubs easily. A good example of this is the fact that cyanoacrylates may be removed from human skin using abrasive materials (such as sugar or sandpaper).

Cosmetic uses:

Cyanoacrylate is used in the cosmetic and beauty industry as an eyelash extension glue or “nail glue” for some artificial nail enhancers such as nail tips and nail covers.

Medical uses:

Tissue adhesives have been used for a long time in the beauty and medical industry and in first aid.

Hysteron-acrylic glue made by Bebran company is one of the most famous and high-quality glues available in the medical market in the world.

Today, cyanoacrylate glue is widely used in a wide range of surgeries.

Cyanoacrylate glue guarantees high-quality adhesion and biological compatibility compared to other types of glue. Due to the polymerization process, when cyanoacrylate glue comes in contact with blood or tissue water, it forms a strong and strong coating.

Medical Applications of cyanoacrylate glue

Urinary fistula, digestive fistula, lymphocele, endoscopic procedure, laparoscopy, bladder tumor evacuation, cutaneous ureteral fistula, partial nephrectomy, tumor gap, varicocele, venous-arterial fistula, hypospadias, priapism, skin gap closure, children’s urology, mesh fixation and…

Skin damage

Cyanoacrylate adhesives may stick to body parts, and injuries may occur when parts of the skin peel off. However, without force, the adhesive will peel off the skin on its own in time (up to four days). In the case of a glued eyelid, especially if it is in contact with the eyeball, medical professionals are indicated.

Toxicity

Heat depolymerizes the cured polymers and produces gaseous products that are highly irritating. They are immediately polymerized and rendered ineffective by the moisture present in the membranes. These risks can be minimized by using cyanoacrylate in well-ventilated areas. About 5% of the population may become sensitized to cyanoacrylate vapors after repeated exposure. Cyanoacrylate may also be a skin irritant and cause an allergic skin reaction. In rare cases, inhalation may cause ascites. There is no specific measure of toxicity for cyanoacrylate adhesives because many adhesives contain different formulations of cyanoacrylate.

The 2-octyl cyanoacrylate compound degrades much more slowly due to its longer organic backbone (a series of covalently bonded carbon molecules) and the adhesive does not reach the tissue toxicity threshold. Due to the toxicity of ethyl cyanoacrylate, the use of 2-octyl cyanoacrylate is preferred for sutures.

Solvents

Acetone in nail polish remover is one of the most available solvents for softening cyanoacrylate and removing stuck parts. Other solvents are nitromethane, dimethyl sulfoacid. Gamma butyrolactone can also be used to remove dried cyanoacrylate.

Important points in the field of use

In order to use cyanoacrylate glue, it should be applied as a thin layer on the desired surface. The point that is important during use is that the surface is clean and dry, and if a thick layer of it is poured on the surface, the connection will not be done properly. When using cyanoacrylate adhesives, ensure proper ventilation of the workplace, as adhesive vapors will be present in the bonding area. Since cyanoacrylate drop adhesives have high adhesion to all kinds of materials – especially human skin – it is recommended to wear gloves when using them. Also, these adhesives react quickly and generate heat with cotton, wool, leather, etc., and caution should be used when using them.

Finally, one thing that should always be kept in mind is that there are many factors to choose the right cyanoacrylate glue for your application. Due to the great variety of this type of adhesives, be sure to get technical advice from our specialist before buying, so that you can buy the best drop adhesive according to the type of surfaces and your specific usage conditions.